Quick Guides

Switching Cans:

Please use caution when switching an empty can with a full can of foam. We recommend wearing nitrile gloves, goggles, long sleeves and long pants. Before taking the can of foam off the PurShooter or Pageris gun go to a plastic lined trash bag and pull the trigger & empty the contents into a trash bag. Hold the trigger until all the foam & propellant are out of the gun. Put the system on a flat surface with the bottom of the can on the table and the dispensing gun pointing skyward; carefully unscrew the gun upward off the can of foam. Promptly take the foam gun and screw it downward on the replacement can of foam. Listen for the valve to open with a little purging noise. Once the new can is on the gun, go over to the plastic lined trash bag and pull the trigger for 3 to 5 seconds to purge any moisture that may have entered into the gun. For disposal of the completely empty can please check with your local authorities.

Foaming Around Windows and Doors:

One component moisture curing polyurethane gun dispensed foam is an excellent product to use around windows and doors to stop the passage of air. Purfill WF has excellent adhesion qualities. We are air sealing, not insulating. With Insulation more is better, but this is not true when air sealing around windows & doors. When foaming around windows & doors the goal is to match the thermal resistance factor (R factor) of the window. Most windows have an R-factor of 2 or 3. Purfill WF has an R-factor of 5 per inch. Therefore 3⁄4 of an inch of foam should be sufficient to match the R-Factor of the window. Place the foam as close to the exterior as possible, then follow these simple instructions: *** Shake the can very well *** Assure the can temperature is between 60 – 80 degrees Fahrenheit *** Practice laying down beads of foam. Play with the set screw on the foam gun & leave the setting when desired bead size is dispensed. *** Assure the window is clean and dry, to maximize good adhesion ***Foam from the top to bottom, placing the foam gun barrel into the void and foam down the window *** For small voids, use our foam reducer or plastic barrel with the green needle; dispense the foam slowly when using these adapters. *** When foaming is complete, let the foam properly cure, review the window and look for any void and us the foam to touch up where needed.

Foaming In Cold Weather:

You get excellent quality foam while foaming in cold weather if you follow these simple steps: *** Shake the can well ***Assure the can of foam temperature is between 60-80 degrees Fahrenheit *** Mist water on the area to be foamed. Warm the can of foam before foaming in cold weather. Warm by keeping in your vehicle, by placing the can in hot water, etc. “Never” use fire or flame to warm a can of foam. Shake the can very well for at least 30 to 60 seconds. With a misting bottle, mist the area with water on the area to be foamed, if you are foaming in large sections. Every two inches, stop, mist water on the foam and foam another 2 inches. In colder temperature, the humidity is dryer and there is less moisture in the air, hence the need to mist water to assure proper curing.

Shelf Life:

All aerosol products have a shelf life. Polyurethane foam products can range in shelf life from 9 months to 2 years. Shelf life is dependent on the valve system that is being used. We use predominately the Pageris Valve. This is the highest quality valve on the market. It is made with only plastic and metal components, thereby eliminating any storage issues. Most other foams use a rubber valve system. These rubber valves expand and contract while in storage due to temperature fluctuations which then can allow the propellant to escape the can and ruin the foam. Our plastic and metal valve does not expand or contract with weather fluctuations. For the best storage, store our cans of foam in an upright position in a dry constantly moderate temperature.

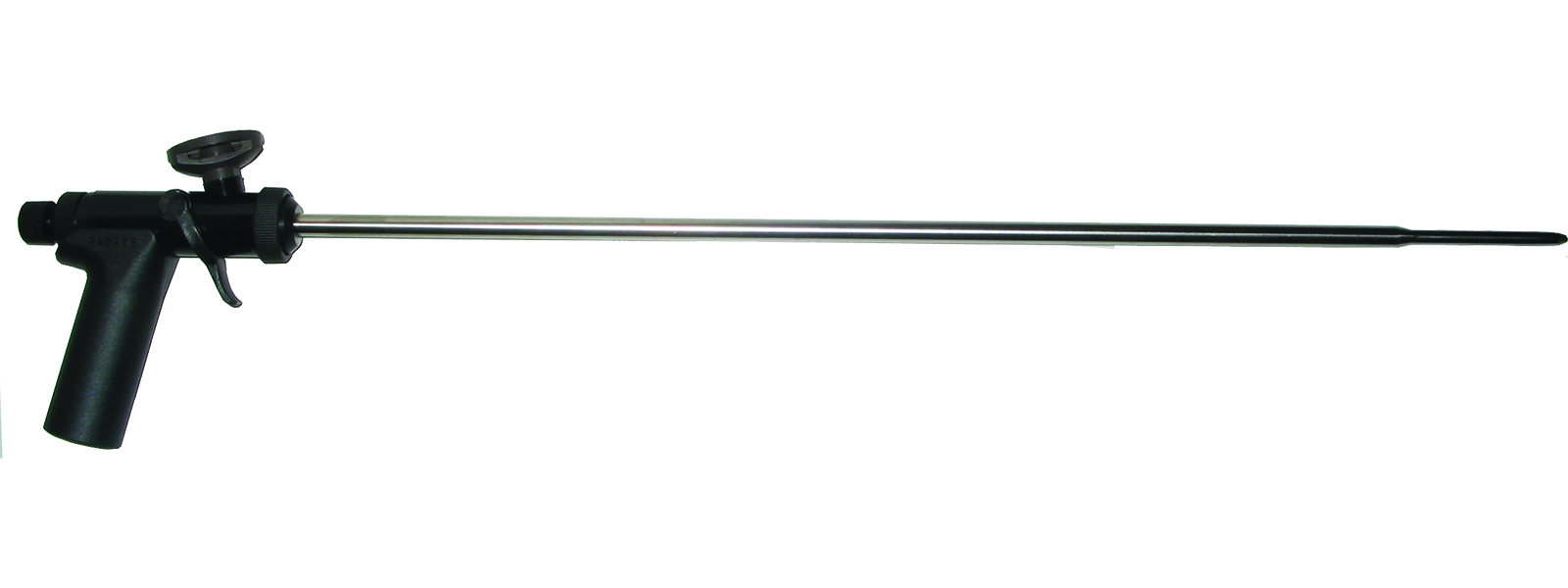

Why No Cleaner:

We believe if you “ALWAYS LEAVE A CAN ON THE GUN & PULL THE TRIGGER ON A REGULAR MONTHLY BASIS” there shouldn’t be a need to purchase gun cleaner. Our foams are moisture curing, with the can mounted, the system is moisture free. Pulling the trigger/using the system monthly keeps fresh foam flowing through the system. Most cleaners are acetone which can collapse the polyurethane into a thicker polyurethane resin. The use of cleaner is time consuming, expensive and can lead to the polyurethane resin to enter the gun and coat the inside. Always leave a can of foam on the gun; it doesn’t matter if the can is empty or full.